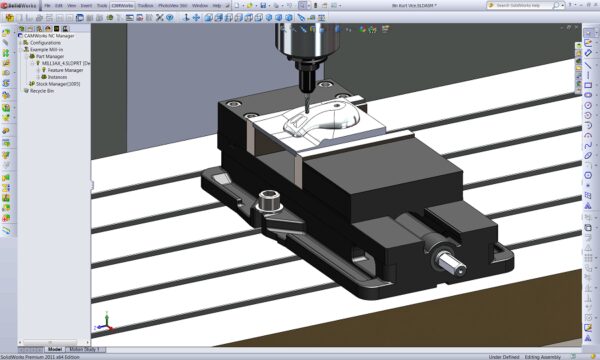

The part can be easily adapted to the needs of processing by, for example, eliminating redundancies from the point of view of processing elements of geometry or by recalculating the executive dimensions of the model into the middle of the tolerance field. When adding any technical data to the SolidWorks model, such as roughness designations, bases, shape tolerances, and surface locations, dimensional tolerances, the programmer always has direct access to them, which makes it easy to select the part based on the machine and select ensuring the specified quality of the tool part and cutting conditions. This ensures complete associativity of the model and tool paths, which leads to automatic updating of all tool paths when making changes to the model. The programmer’s results are stored in the same model part or assembly, SolidWorks. Processing is carried out directly in the SolidWorks environment and the SolidWorks model. Overview of CAMWorks for Solidworks Benefits

0 kommentar(er)

0 kommentar(er)